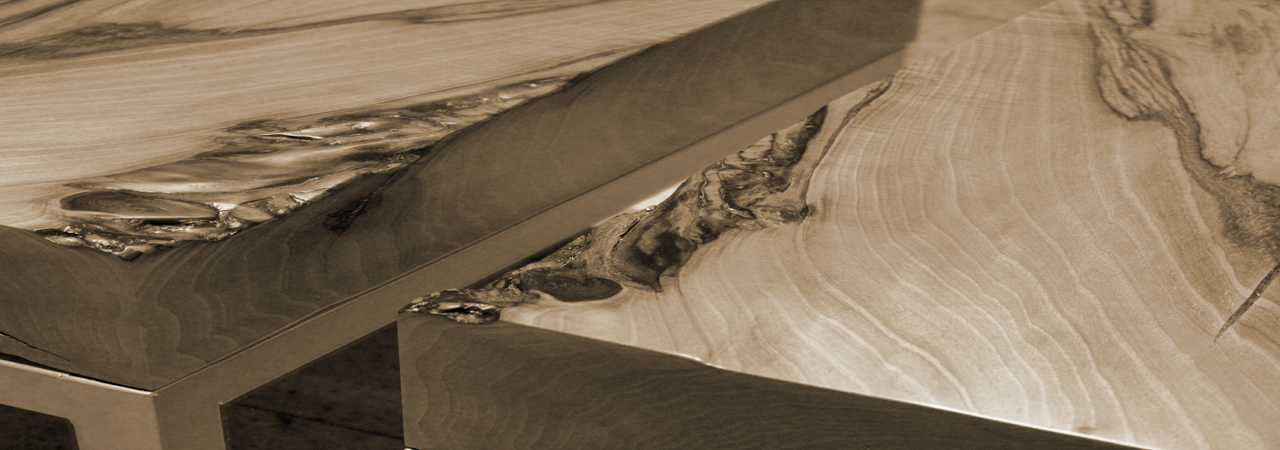

Modeling of coffee table

Formation of a unique table made of tree roots and wood anomalies

Some time has to go by before our product shines in full glory. First of all, we need to find appropriate piece of wood (root, trunk, anomaly, etc.). Looking at the chosen piece of wood we can imagine the final product. Sometimes we come across to it while walking through the forest or driving a car. We take it home and we clean the soil from it. It is the best for product to lift it from the ground so that there is natural seasoning. Therefore there is less tension in the wood and less cracks that are common consequences of technical seasoning. Seasoning in workshop is followed which exterminates wood pest (insects, fungus).

After a few months of technical seasoning the wood is processed on woodworking machines. Then there follows rough product design that is based on a prior conception and later we have to sand the wood a few times that we get the final shape and the smoothness of the surface. The products with glass plate should be designed in the way that the glass completely fits on the consctruction. In that phase we make the pattern for glass production. After the procedure the product is ready for varnishing. We can apply wax or polyurethane varnish on. After the first varnishing the product needs to be milled again and then comes the final varnishing. At the end we add our logotype and slippers that protect any damage on the floor while moving the product across the flat. So, the product is finishid and it waits to be taken in new home.

You can reach us on jene.jurij@gmail.com. We are happy to answer all your questions and give you the information you need.